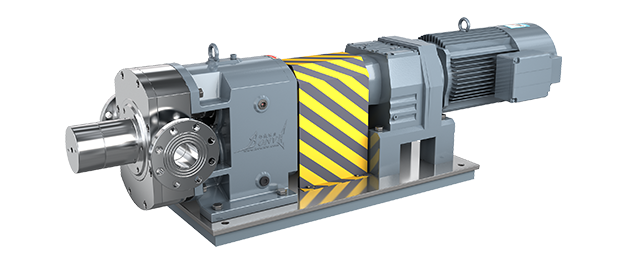

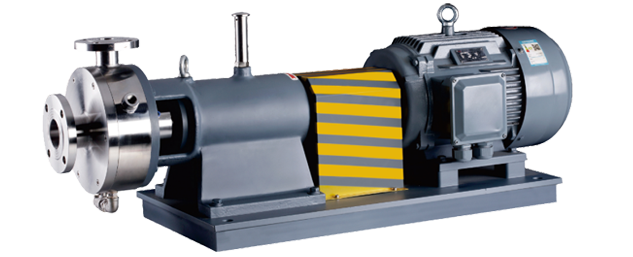

In the production process of adhesives due to the neutralization reaction before the various monomer viscosity is not high but in the process of neutralization viscosity will change with the temperature change, so the viscosity range of the conveying equipment required to adapt to a wide range, and in the degassing and dehydration there is also the existence of negative pressure, that is, the pump's self-absorption is also a stringent requirement. Bonve rotary pumps to the application of technology as the benchmark for the requirements of different conditions, the pump clearance, finish, sealing, etc. Make special customization, conveying materials smoothly and safely with high efficiency. The Bonve Rotary Lobe Pump is specially customized to meet the requirements of different working conditions, such as pump clearance, finish, sealing, etc. It can transport materials smoothly and safely with high efficiency.

Industry Cases

Industry Cases