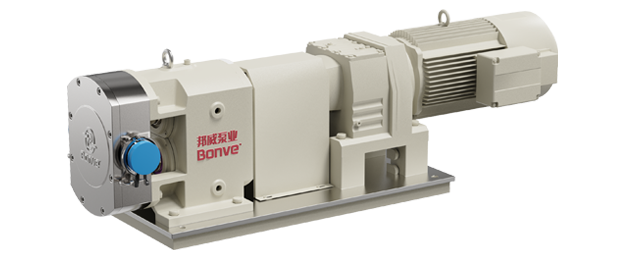

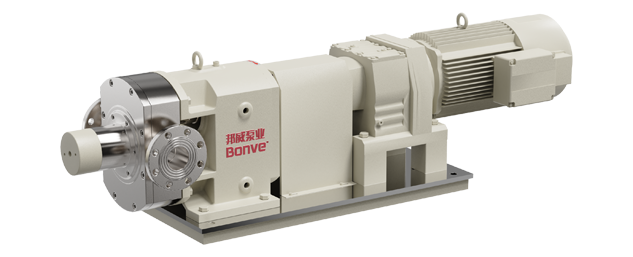

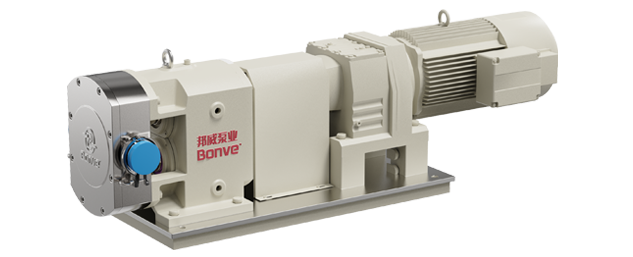

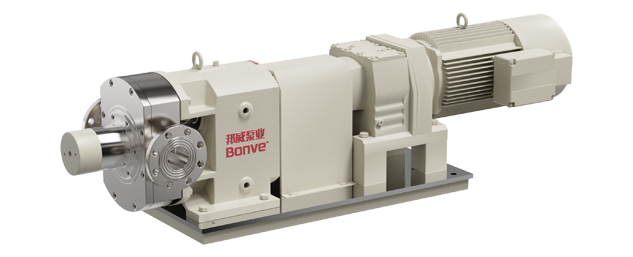

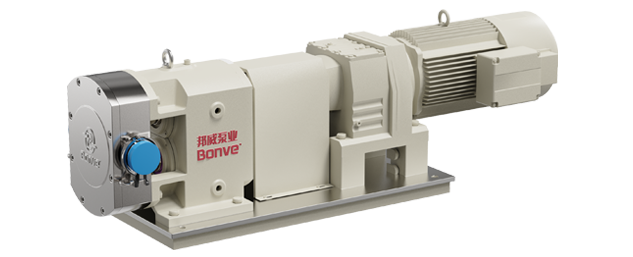

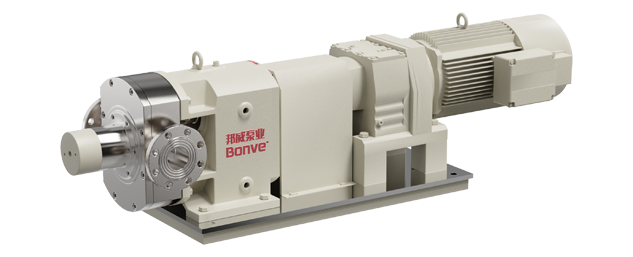

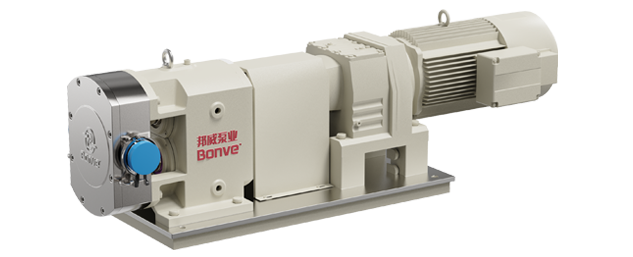

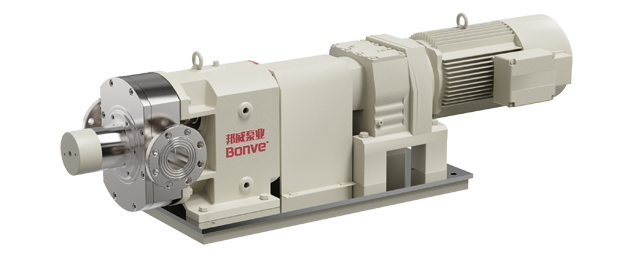

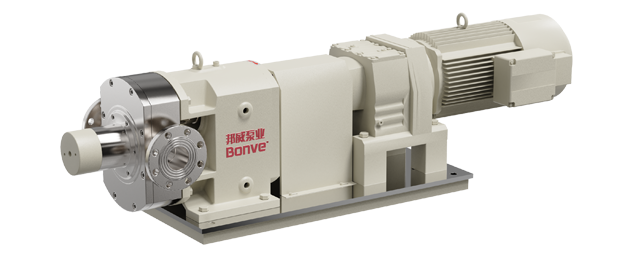

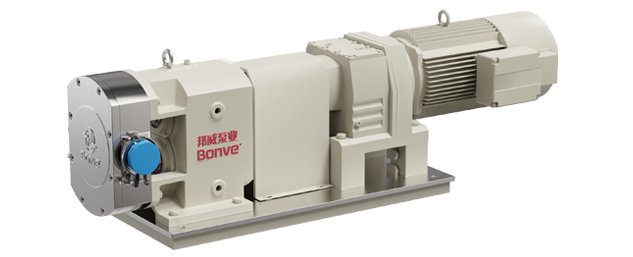

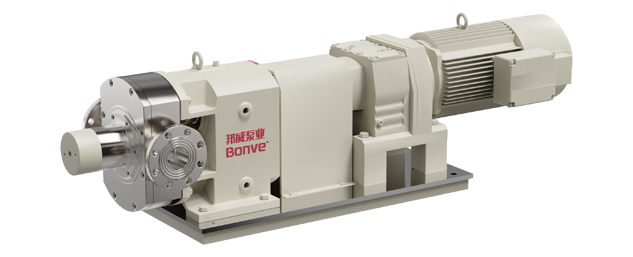

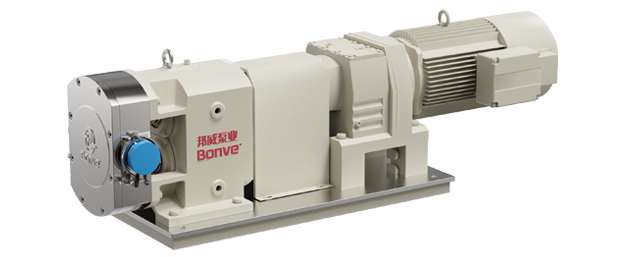

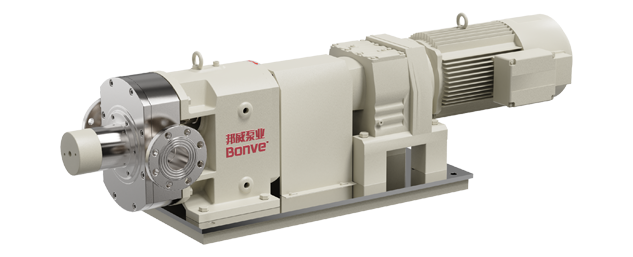

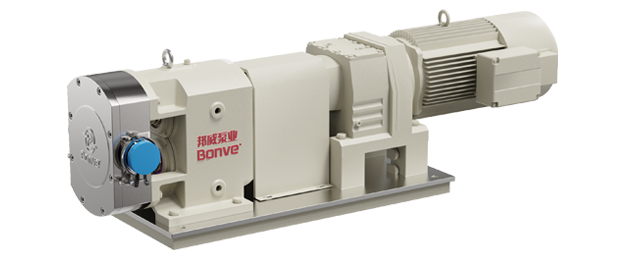

Homogenizing and emulsifying pump is used in the process of heavy cake (waffle cake, gongfu yao, etc.), which is mainly to homogenize and mix and refine the mixture of flour, egg, butter, and so on. Traditional equipment using whisk to deal with the material, but the whisk high cost, large size, motor energy consumption, and homogenizing emulsifying pump compared to the whisk small size, motor energy consumption is small, and the processed material is more delicate, so it has a higher cost-effective, and gradually replaced the whisk in some working conditions.

Industry Cases

Industry Cases