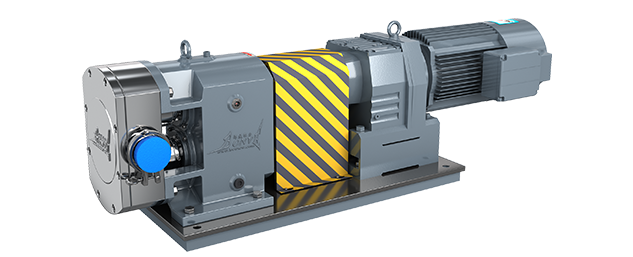

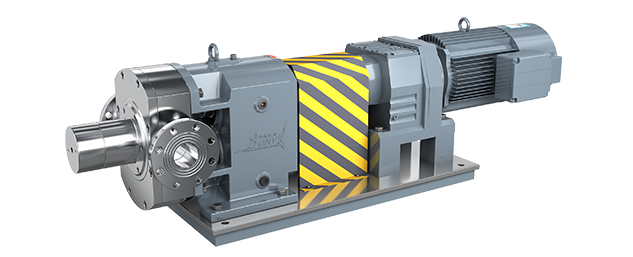

Bonve cam-type Rotary Lobe Pump are widely used in daily chemical industry, due to the low speed operation, the pump is especially suitable for conveying easy to foam, high viscosity, high concentration and abrasive media, the medium after its conveyance to maintain the original quality unchanged, do not have any physical and chemical reaction. Pump rotor and rotor, rotor and pump body to maintain a certain gap between, no friction coefficient, long service life. Compact structure, easy maintenance, almost no wearing parts, low operating costs.

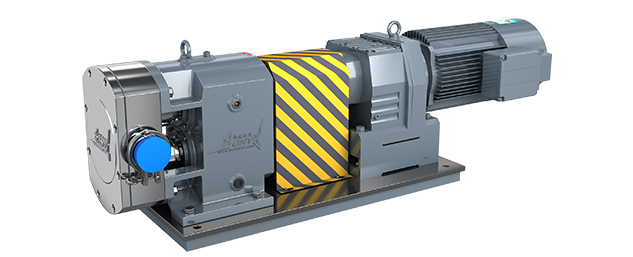

Industry Cases

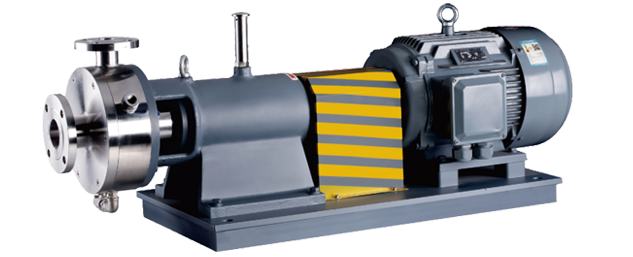

Industry Cases