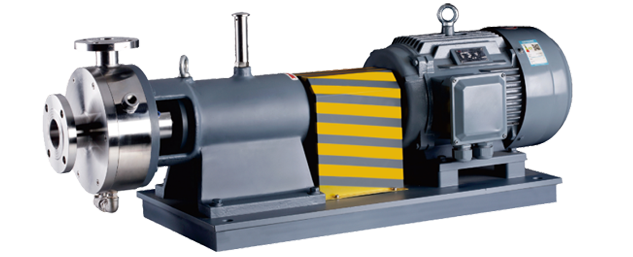

Pharmaceutical grade Rotary Lobe Pump have high sanitary and clean technical requirements, Bonve pharmaceutical grade Rotary Lobe Pump, the surface roughness of the overflow parts reaches 0.2~0.8um, and are manufactured in strict accordance with the national technical specifications for pharmaceutical equipment. The products are widely used in ointment, dip, emulsion, pill paste, medical syrup, vitamins, fermentation solution, pharmaceutical intermediates and other materials transportation, while Bonve homogenizing emulsifying pumps are also widely used in the pharmaceutical industry. Bonve Rotary Lobe Pump in all kinds of drug preparation production process to form a complete, scientific and efficient fluid transportation system, with high hygiene level, stable transmission and less wearing parts, easy disassembly and maintenance, high efficiency and energy saving features. Bonve Rotary Lobe Pump are characterized by high hygiene level, stable conveying, few wearing parts, easy disassembly and maintenance, high efficiency and energy saving, etc. The products have been certified by the U.S.A. 3A, FDA and so on, and conform to the GMP standard.

Industry Cases

Industry Cases