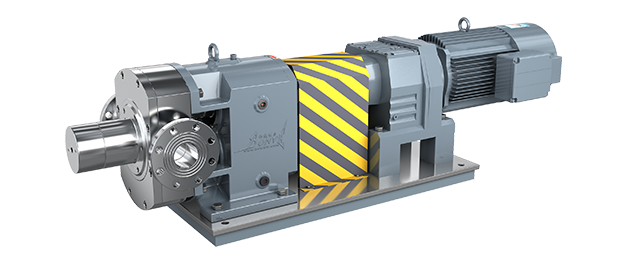

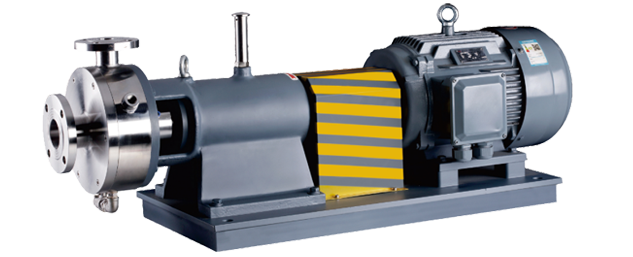

Bonve Rotary Lobe Pump, grinder pumps, mixing and Homogenizer Mixer Pump are widely used in the viscose slurry gruel, polyvinyl chloride slurry, acrylic slurry, spandex slurry, polyester slurry, polypropylene slurry, polyester chips, man-made fiber slurry and functional fiber slurry industries such as a variety of high-viscosity material transfer, as well as the need for crushing, grinding, mixing, homogenization, emulsification and other types of production process requirements.Bonve Rotary Lobe Pump for chemical fibers, products. Bonve Rotary Lobe Pump for chemical fibers are characterized by delicate design, precise processing, high conveying efficiency, long service life, low maintenance cost, stable and efficient operation, safety and environmental protection.

Industry Cases

Industry Cases