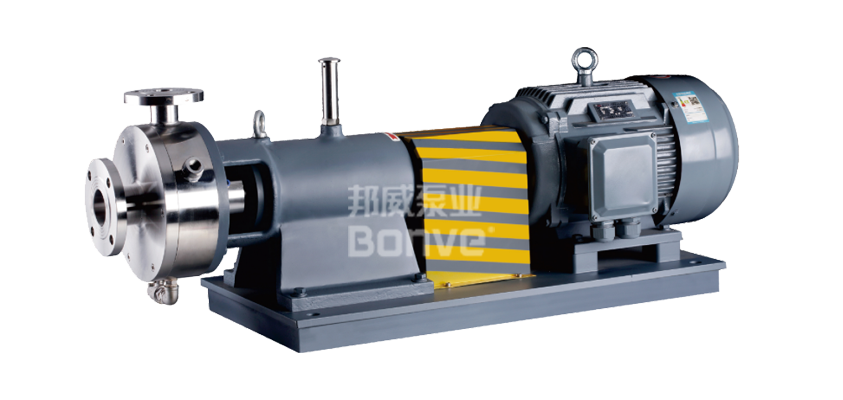

Bonve FHM1 Homogenizer Mixer Pump

Product Overview

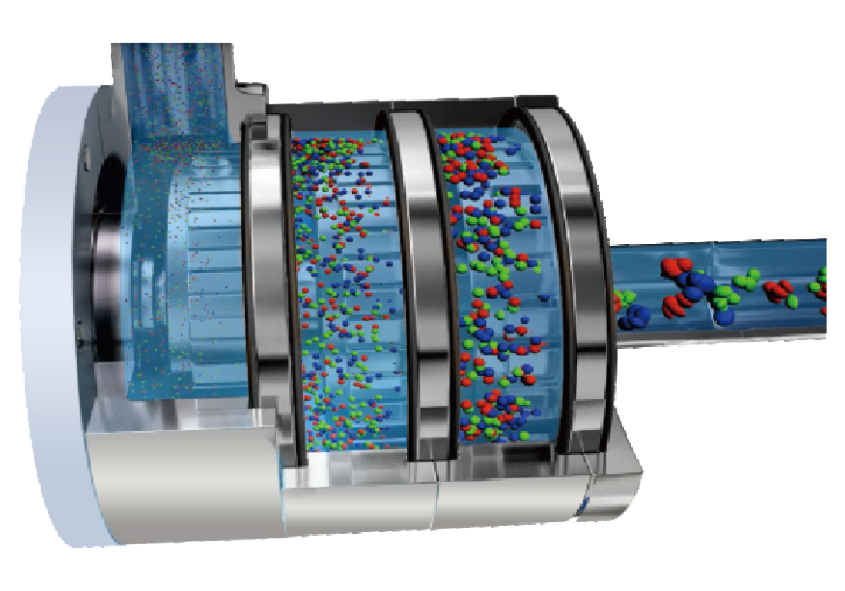

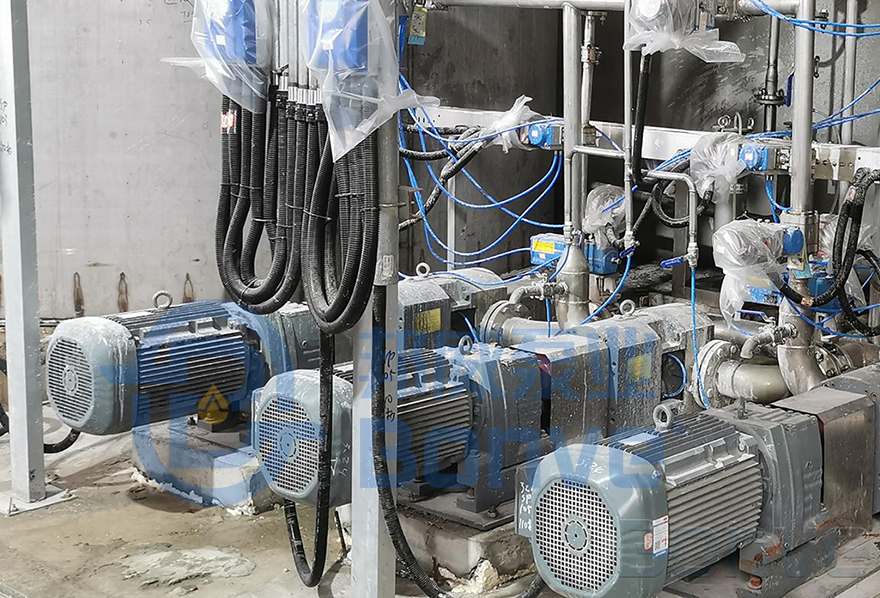

FHM1 series mixed homogenizing emulsifying pump is equipped with a set of stator and rotor in the pump chamber. The rotor drive shaft is made of high-strength stainless steel, and the sealing device is a double-face water-cooled mechanical seal. The pump shaft is supported by a bearing box and connected to the motor through a coupling. The working principle of the product is to suck the material from the inlet, carry out comprehensive homogenization and emulsification, and then discharged from the outlet. It is suitable for cyclic processes in small and medium batch production, as well as for short-distance conveying and homogenizing emulsification work.

Overcurrent material

SS304/SS316/SS316L/other than

Connection Method

Flange/Screw-on/Clamp/Other