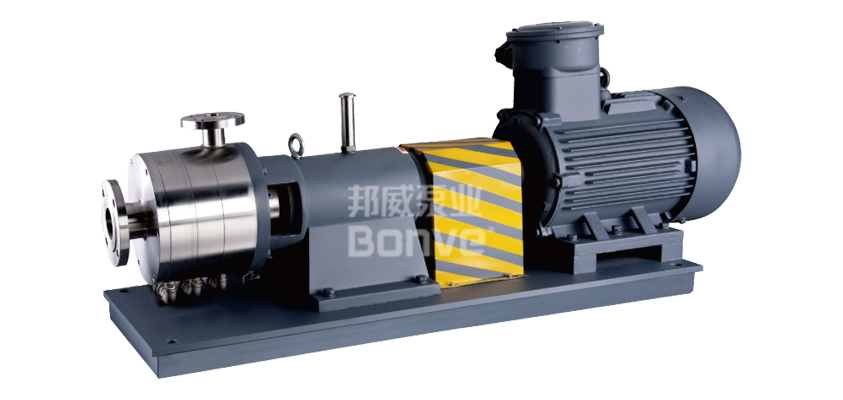

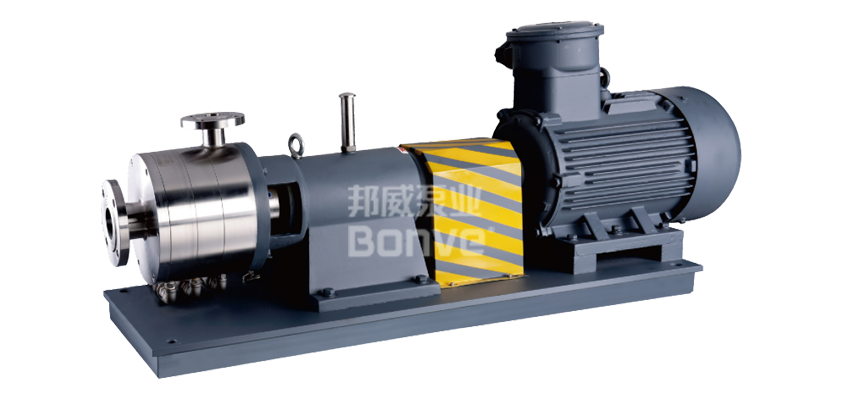

Bonve FHM3 Mixing Homogenizing and Emulsifying Pumps

Product Overview

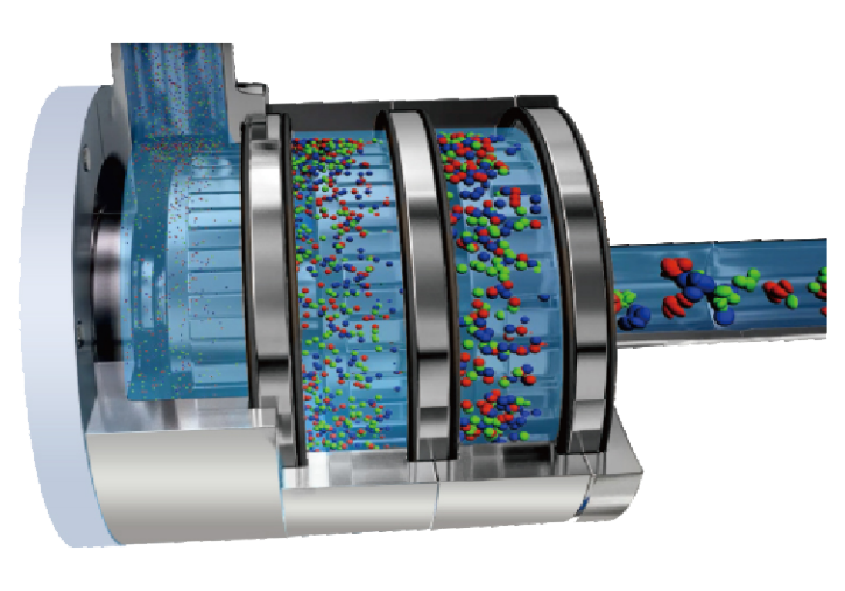

FHM3 Homogenizer Mixer Pump is extended and developed on the basis of FHM1 type, its working chamber is composed of three sets of rotor and stator, and the materials are dispersed, finely and emulsified step by step through the rotor and stator, which is a kind of high-efficiency ultrafine Homogenizer Mixer Pump that integrates mixing, dispersing, crushing, dissolving, finely, decondensing, homogenizing, emulsifying and conveying. The sealing device of this product adopts double end face water-cooled mechanical seal, and according to the user's needs, it can be equipped with heating and heat preservation or cooling device.

FHM3 homogenizing and emulsifying pump is suitable for large and medium batch continuous on-line production or circulating treatment production process. After using this series of products, the original traditional production process is further simplified, production efficiency is greatly improved, and product quality is significantly improved.

Overcurrent material

SS304/SS316/SS316L/other than

Connection Method

Flange/Screw-on/Clamp/Other