Bonve general purpose Rotary Lobe Pump

Product Overview

Overcurrent material

SS304/SS316/SS316L/Other

Connection Method

Flange/Screw-on/Clamp/Other

SS304/SS316/SS316L/Other

Flange/Screw-on/Clamp/Other

| Models | Displacement (L/r) | Rotation speed (r/min) | Flow rate (m³/H) | Discharge pressure (Mpa) | Vacuum(Mpa) | Inlet/outlet Dia. (mm) | Maximum viscosity(cp) |

|---|---|---|---|---|---|---|---|

| 25BV12-05 | 0.06 | 10-1000 | 0-0.5 | 0-1.2 | -0.080 | 25 | 1,500,000 |

| 40BV12 -2 | 0.15 | 10-1000 | 0-2 | 0-1.2 | -0.080 | 40 | |

| 50BV12-5 | 0.32 | 10-800 | 0-5 | 0-1.2 | -0.085 | 50 | |

| 65BV12-10 | 0.65 | 10-600 | 0-10 | 0-1.2 | -0.085 | 65 | |

| 80BV12-20 | 1.74 | 10-500 | 0-20 | 0-1.2 | -0.095 | 80 | |

| 90BV12-30 | 2.60 | 10-500 | 0-30 | 0-1.2 | -0.095 | 100 | |

| 100BV12-40 | 3.65 | 10-500 | 0-40 | 0-1.2 | -0.095 | 100 | |

| 125BV12-50 | 4.60 | 10-500 | 0-50 | 0-1.2 | -0.095 | 125 | |

| 140BV12-70 | 6.10 | 10-500 | 0-70 | 0-1.2 | -0.095 | 150 | |

| 150BV12-80 | 7.63 | 10-500 | 0-80 | 0-1.2 | -0.095 | 150 | |

| 200BV12-120 | 11.56 | 10-400 | 0-120 | 0-1.2 | -0.095 | 200 | |

| 250BV12-150 | 14.22 | 10-400 | 0-150 | 0-1.2 | -0.095 | 250 | |

| 300BV12-200 | 20.8 | 10-300 | 0-200 | 0-1.2 | -0.095 | 300 |

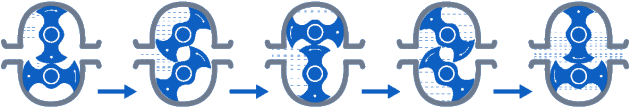

Bonve cam-type double Rotary Lobe Pump adopts two synchronous running rotors, which are driven by a pair of synchronous gears in the box body, and the rotors rotate in the opposite direction synchronously under the driving of the main and vice shafts, so that the volume of the pump changes, which constitutes a higher vacuum and discharge pressure, and effectively conveys the medium. Rotor and rotor, rotor and pump body to maintain a certain gap between, no friction coefficient, long service life, the transported media does not destroy its composition, not any physical and chemical reaction.

Bi-wing rotors diagram

Tri-lobe rotors diagram

Rotor to rotor, rotor to pump body to maintain a certain clearance, no friction coefficient

All core components are processed by imported machining centers

High Precision

Simple assembly and disassembly, easy maintenance, cleaning, less wearing parts

Energy-saving, low failure rate

Reliable sealing, low noise

After configuring the frequency converter, the flow rate can be adjusted at will

and can be used as a general metering pump.

Flange type, screw type, clamp type, etc. are available.

Slurries with a viscosity of up to 2 million

cp and a solids content of up to 70% can be conveyed.

Conveying vapor, liquid, solid and other three-phase mixtures of materials.

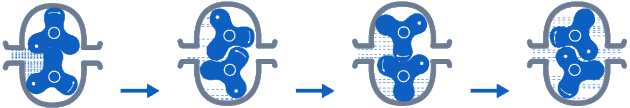

BREAKDOWN DRAWING

Rotors: High-precision imported machined cam rotor with very small error, unique cam-type rotor perfectly seals and isolates the inlet and outlet of the pump, and the vacuum degree is as high as -0.095 MPA.The material and type of the rotor can be selected according to the characteristics of the material to be conveyed.

Axle: The drive shaft is processed by imported machining centers, featuring high precision, high bending strength and high resistance.

Pump Chamber: The pump chamber is sealed by a pump cover that can be opened quickly, realizing quick maintenance of the pump. The pump body is machined by imported machining centers, and the pump body is processed in strict accordance with the US 3A standard to meet the requirements of CIP and SIP.

Gears: High-precision and high-standard synchronous gears have good meshing, smooth transmission, low noise, and excellent load-bearing capacity.

Machine Seal: According to the different characteristics of the material, targeted use of the seal form and material to ensure zero leakage, no pollution, more environmentally friendly.

Bear: The six separately arranged bearings increase the concentricity of the pump operation, enhance the bearing capacity of the shaft and make the pump run more smoothly, thus increasing the service life of the shaft and seal.

Gearboxes: The gear box is processed by imported machining center with high precision, high concentricity and high versatility.

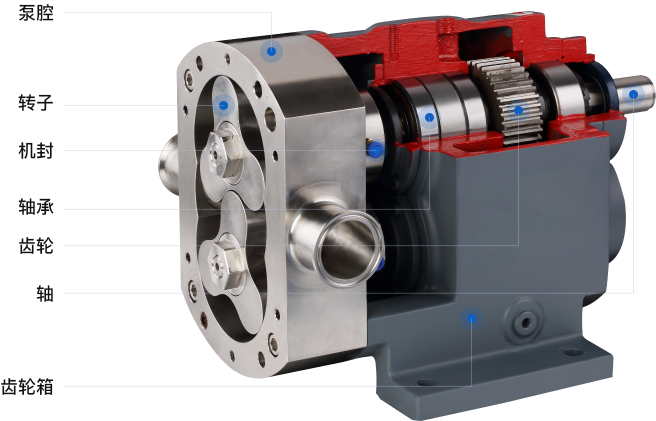

An oral care company uses Bonve cam-type double Rotary Lobe Pump.

An oral care company uses Bonve cam-type double Rotary Lobe Pump.

Daily use industry applications

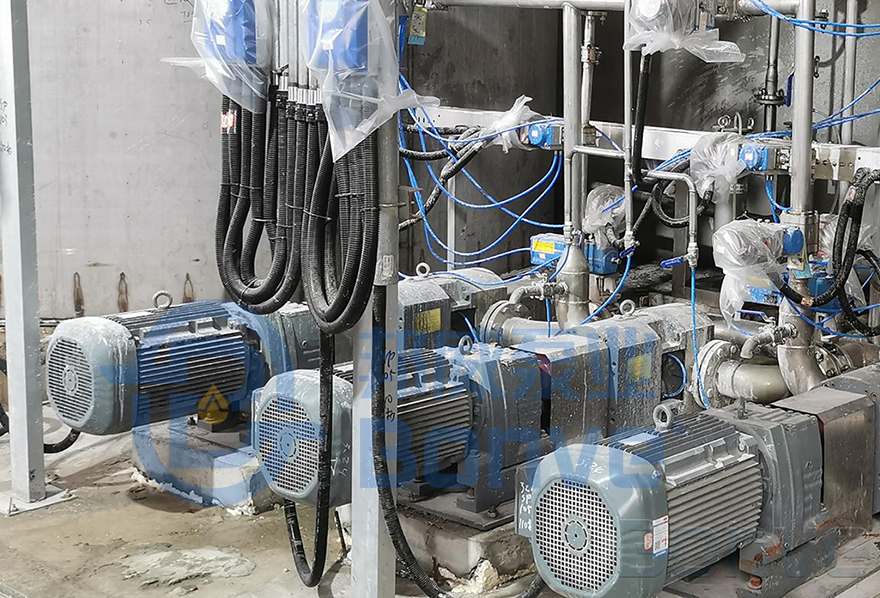

Read More An epoxy resin production line using cam-type double Rotary Lobe Pump

An epoxy resin production line using cam-type double Rotary Lobe Pump

Fine Chemical Industry

Read More

Pre Sales Application Technology Exchange

Technology Solutions

Partner

Contact Us