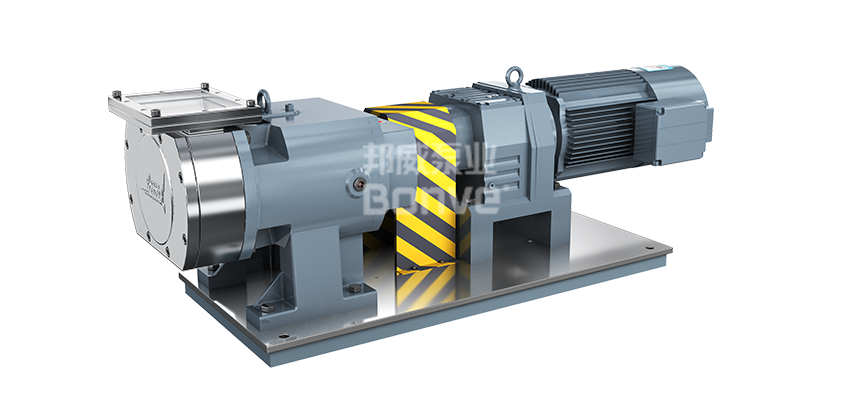

Bonve V-type inlet type Rotary Lobe Pump

Product Overview

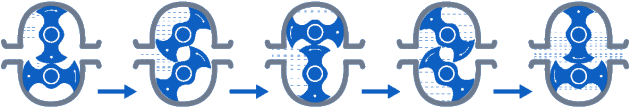

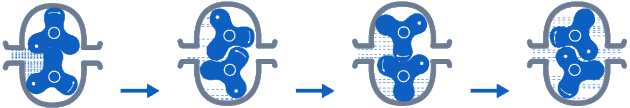

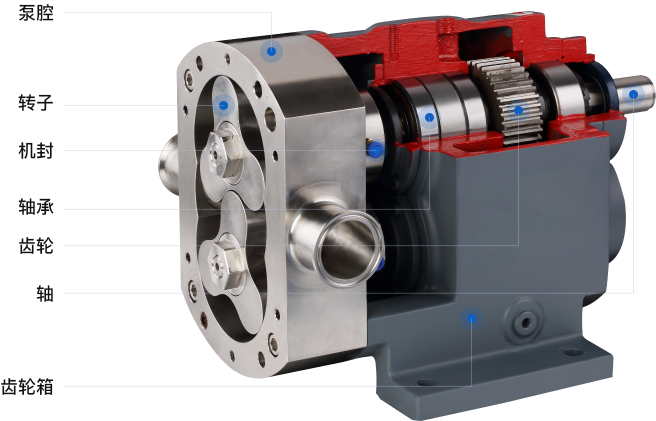

Bonve cam-type double Rotary Lobe Pump is Bonve company for various industries in more than 3,000 kinds of fluids to explore and design, especially suitable for high viscosity, high solid content, corrosive fluids efficient transportation. Over the past ten years, Bonve cam-type double Rotary Lobe Pump have been developed to the fourth generation of products, which further extends the service life of the pump. The fourth generation of pumps is widely used in various fields thanks to the innovative structural design and the accumulation of customer application experience.

Overcurrent material

SS304/SS316/SS316L/Other

Connection Method

Flange/Screw-on/Clamp/Other