I. Challenges in Food Conveying

Traditional pumps face core pain points—pressure fluctuations, bacterial retention, and sanitary dead corners—when handling viscous food materials like tomato paste or pumpkin caviar:

Tomato paste’s high viscosity causes unstable pressure in pump cavities, leading to filling deviations or leaks.

Traditional rotor compression nuts and rough inner walls create sanitary dead corners, raising bacterial contamination risks.

Particle abrasion in pumpkin caviar accelerates pump wear and leakage risks. Poorly sealed designs trap residue, amplifying hygiene and quality control issues. These shortcomings fall short of the industry’s demands for efficient, stable, and hygienic operations.

II. Bonve’s Intelligent Food Conveying Solutions

Model: 100BV12-40 Cam Rotor Pump (4th Gen)

Extreme Pressure Resistance: 6 bar system pressure, overcoming high-pressure filling challenges for tomato paste.

Smart Speed Control: 20–40 m³/h wide flow range + VFD motor, precisely adapting to pumpkin caviar processes.

Wear-Resistant Core: SS304 food-grade stainless steel + tri-lobe helical rotors, compatible with acidic sauces and significantly anti-adhesive.

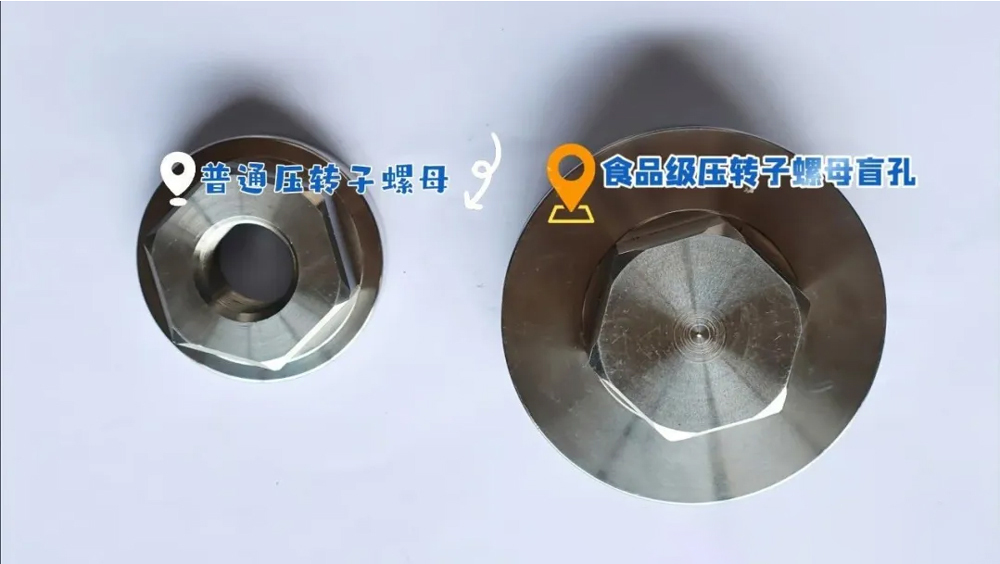

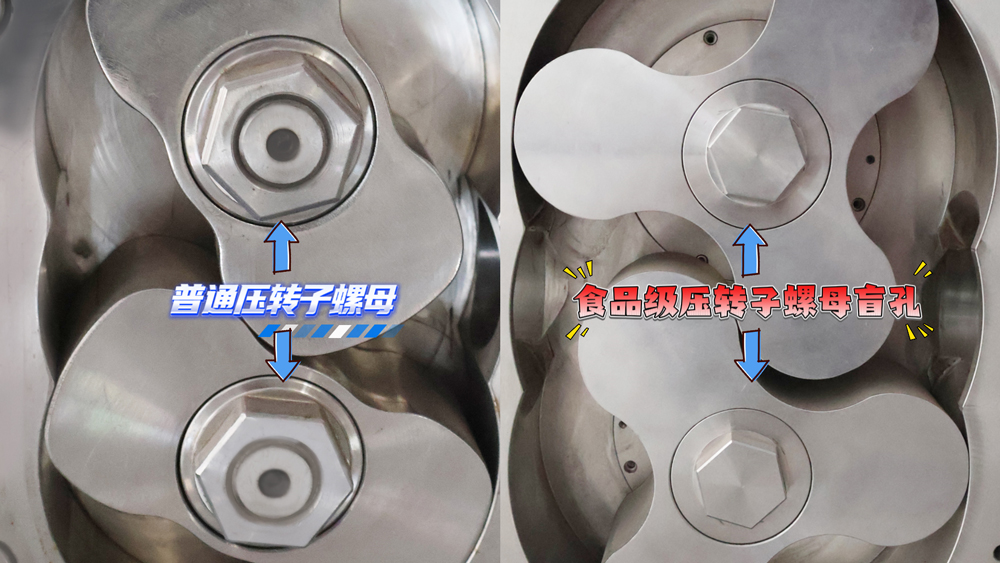

(Rotor Compression Nut Comparison)

Hygienic Revolution: Food-grade blind-hole design for rotor compression nuts (zero dead corners) + DN100 clamp-type quick-release connections for easy residue cleaning.

Zero Leakage: Single-end water-cooled mechanical seal eliminates seepage risks.

Stable Output: 230 rpm optimal speed with minimal fluctuation, ensuring uniform material transfer.

III. Bonve’s Expertise in Food Conveying

With over a decade in the food industry, Bonve Pumps leverages extensive experience and successful cases to deliver tailored, reliable conveying solutions for diverse operational challenges.

(Bonve 100BV12-40 Food-Grade Cam Rotor Pump)

Why Bonve Cam Rotor Pumps Excel in Food Applications:

· Ultra-Hygienic: Contact materials: SS304/316/316L.

· High Smoothness, Surface roughness ≤0.8μm; compliant with CE, 3A, EHEDG, FDA.

· CIP/SIP Compatible.

· Easy Maintenance,Simple disassembly, minimal wear parts.

· Low-Speed & Low-Shear,Preserves product integrity (e.g., avoids damaging delicate ingredients).

Typical Media Handled:

Chocolate, condensed milk, yogurt, honey, syrup, sucrose, tomato paste, fruit concentrates, jam, ice cream, milk, yeast slurry, meat paste, jelly, condiments, soy protein, etc.

Company Profile

Ningbo Bonve Pump Co., Ltd. specializes in manufacturing cam rotor pumps and homogenizing emulsification pumps, delivering customized conveying and mixing solutions worldwide.

Our products serve diverse sectors: papermaking, resin, food, pharmaceuticals, pesticides, coatings, environmental protection, fine chemicals, daily chemicals, and petrochemicals.

By 2024, Bonve has served 8,000+ clients across industries, with 100,000+ pumps operating globally. We innovate relentlessly to provide premium products and build an iconic industry brand.