In industrial equipment,the convenience and reliability of maintenance directly impact the continuity and cost-effectiveness of production systems.Traditional pumps often face challenges such as complex disassembly processes,frequent part replacements,and unpredictable failures,leading to high maintenance costs and production losses.Bonve Cam Rotor Pump,however,achieves effortless maintenance through innovative redesign of operational logic,offering industries a more efficient and economical management solution.

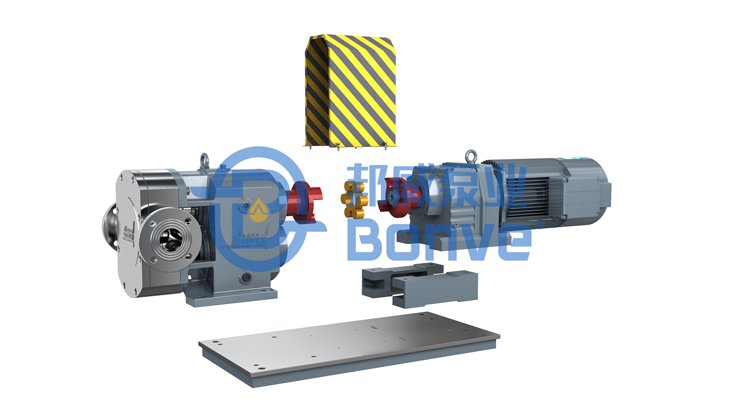

Exploded view of Bonve cam rotor pump

Exploded view of Bonve cam rotor pump

I.Design Innovation:Simplifying Maintenance

The easy maintenance of Bonve pumps stems from essential design philosophy.Traditional pumps use multi-layer nested structures,requiring time-consuming disassembly that risks component damage.Bonve optimizes the structure into a front-opening modular unit,allowing access to all core components by removing partial covers.This breakthrough streamlines maintenance workflows,enabling operators to perform basic tasks without specialized tools.

Synergistic lifespan design of key components further reduces maintenance demands:Bonve combines stainless steel with wear-resistant materials to minimize vulnerable part types,while its contactless rotor system eliminates periodic wear on gears and bearings.In real-world operations,critical components maintain stable performance even after prolonged use.

II.Intelligent Maintenance Technologies

1.Condition Monitoring&Alerts

Embedded sensors track operational status,using AI algorithms to detect risks like seal aging or media abnormalities.The system provides targeted maintenance recommendations before failures occur,shifting from reactive repairs to proactive prevention.

2.Online Maintenance Capability

Operators inject cleaning media via standardized interfaces to complete maintenance without halting production,effectively avoiding line downtime.

3.Intelligent Flushing System

Bonve’s smart flushing system circulates fluid to dissipate heat from friction,preventing seal damage;isolates hazardous media to ensure safety;and flushes away particles to avoid clogging,enhancing seal longevity and system stability.

III.Multi-Scenario Advantages

In the food and beverage industry,Bonve’s rapid maintenance and smart flushing align with automated cleaning needs,drastically cutting service time.Industrial users report lower annual maintenance costs and minimized unplanned downtime compared to conventional pumps.These benefits are critical in 24/7 production environments like chemicals and pharmaceuticals,ensuring reliable operations.

IV.Lifecycle Value Redefinition

Bonve’s maintenance-centric design reshapes equipment value assessment:

-Cost Optimization:Maintains low lifecycle costs through balanced expenditure control.

-Technical Empowerment:Visual maintenance guides standardize procedures,supplemented by targeted training programs.

-Sustainability:Extended lifespan and modular replacement strategies reduce waste,aligning with green manufacturing.

This operational model not only cuts direct costs but also enhances system manageability,driving industries toward precision and digitalization.While traditional pumps struggle with unexpected failures,Bonve users build controllable,efficient management systems.

Bonve Cam Rotor Pump’s easy maintenance embodies a return to industrial equipment’s core value—innovations should serve real user needs.In an era prioritizing smart manufacturing and sustainability,this maintenance-driven philosophy guides fluid transfer equipment from single-function tools to systematic value creators.When maintenance ceases to hinder production,industrial equipment truly becomes a cornerstone of efficiency.